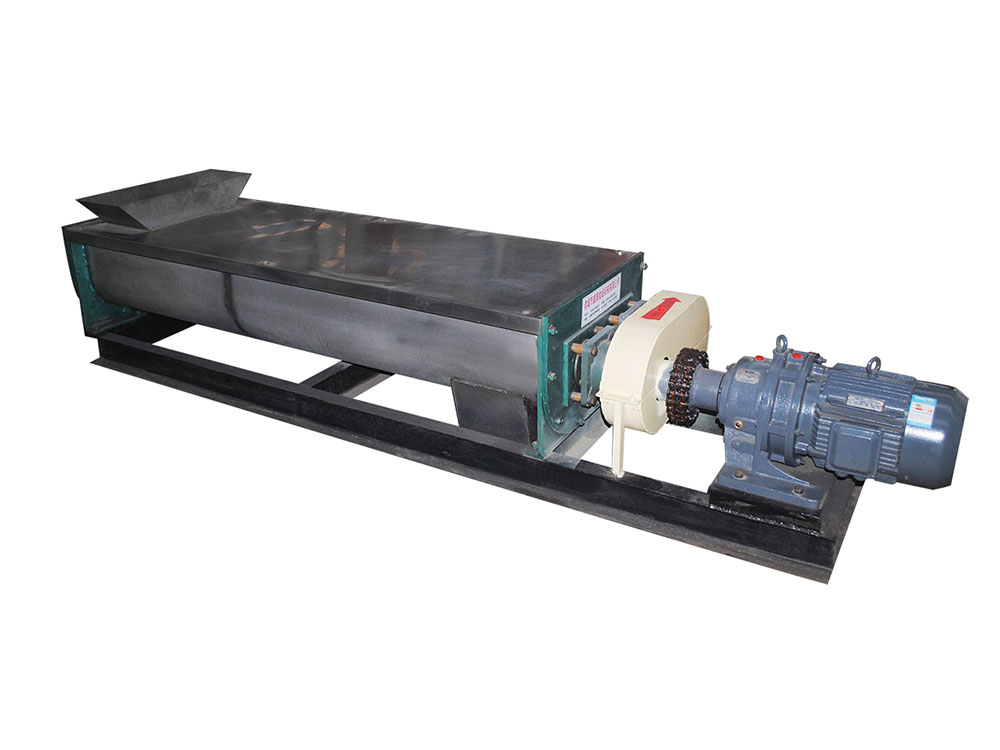

Double shaft mixer machine

The dual-shaft mixer is also known as a wet and dry mixer. The materials in the machine are subjected to compound motion by two rotors in opposite directions. The paddles with animal material rotate counterclockwise along the inner wall of the machine slot, and the animal material is turned left and right. A weightless area is formed at the intersection of the two rotors. In this area, regardless of the shape, size and density of the material, the material can be floated in an instant weightless state, so that the material can form a continuous and cyclical turning in the machine slot, interlaced Cut to achieve a fast and gentle blending effect. The machine adopts a multi-groove labyrinth and packing combined shaft seal, which has a reliable seal and light shaft wear. Uniform humidification, reliable work and low maintenance.

Product features

With the most powerful motor, material can be mixed evenly in the shortest time. It is particularly good at mixing material with big difference in gravity, mesh size, fluidity.

Performance and use

The twin-shaft mixer is mainly suitable for mixing thick and thick slurry of granular dry and wet materials in the starch, alcohol, and feed industries, so that the wet material surface entering the dryer is not easy to stick to the wall. This machine has the advantages of compact structure, uniform stirring, no flying dust, etc., meets environmental protection requirements, and the processing capacity is 5-100 tons / hour. It is an ideal equipment for drying and pulping in the starch industry. The material enters the box through the feeder through the feeder, and the two blade shafts, which are spirally distributed left and right, are rotated synchronously, and the humidified material is continuously pushed out of the feeder.

1. Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321; besides, different material can also be used in combination between the part contact with the raw material and the parts don’t contact with the raw material.

Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer.

2. Reliable driven unit

The driven unit, power and speed are varied according to different raw material, starting method, and processing.Because of the meshing relationship for the paddles, the double shaft driven unit is required to be equipped with synchronous ability.

3. High efficiency mixing unit

According to the properties of raw materials, the paddle can be adjusted and designed accordingly, for example adding wear-proof plate, Teflon plate, and saw-toothed paddle.

Double shaft paddle mixer can be also added high speed breaking bar inside the barrel, scattering material following its flow.

4. Excellent discharging unit

Standard valve for double shaft paddle mixer is twin pneumatic planar flap valves. When close the valve, the planar flaps match the mixing barrel perfectly, this makes no mixing dead zone and better mixing effect.

Characteristics and technical parameters

|

Model\parameter |

HL2600 |

HL3200 |

HL4500 |

HL6000 |

|

|

Maximum import and export conveying distance(mm)

|

2600 |

3200 |

4500 |

6000 |

|

|

Production capacity(T) |

1-10 |

5-15 |

10-20 |

15-25 |

|

|

Spindle speed |

49 |

49 |

46 |

49 |

|

|

Reducer model |

Jzq200 |

Jzq200 |

Jzq350 |

Jzq400 |

|

|

Motor |

model |

Y112M |

Y132S |

Y132M |

Y160M |

|

power |

4 |

5.5 |

7.5 |

11 |

|